Stainless steel

It can be seen everywhere in our life

It has corrosion resistance, high water resistance, high temperature resistance

Beautiful environmental protection, 100 % can be recycled and other advantages

So as a common material

What's the process behind it

We take the stainless steel bathroom cabinet & shower room as an example

Explore the art of a piece of stainless steel

▼Mining

Laterite nickel is mined from the mountains

To provide nickel, chromium and iron for stainless steel

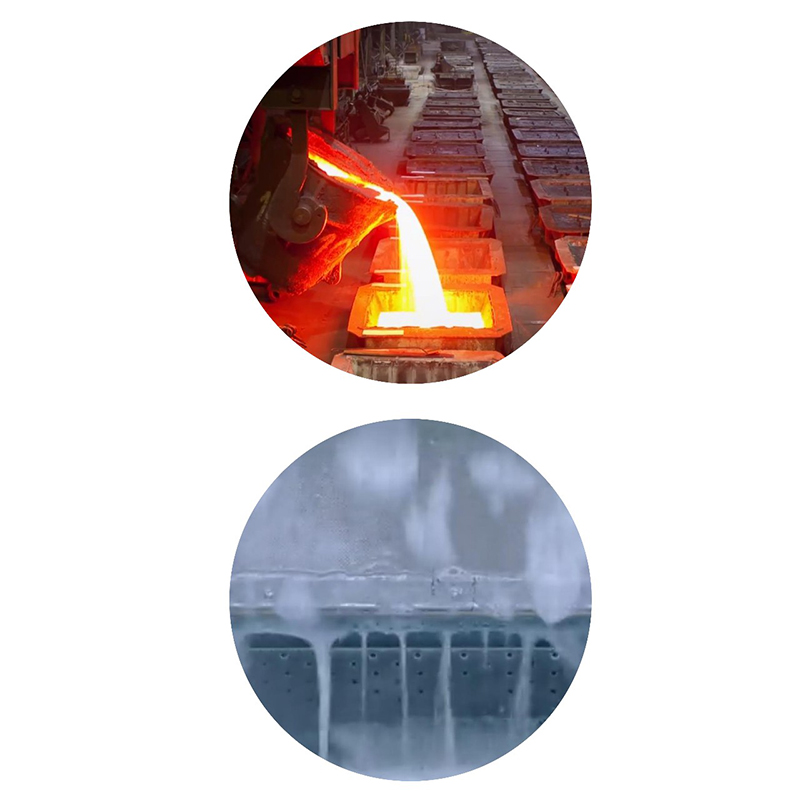

▼ Crude steel smelting

he laterite nickel ore is dried, desulfurized by flue gas and burned into a lump

Then after the initial refining into nickel chromium iron water, into AOD furnace

Other alloying elements are added and refined

After crystallization, cooling, cutting, forming a stainless steel slab

▼ Hot rolled

After heating, the stainless steel slab is roughed, scissor and 8 rolled

Cool to set temperature and roll into steel coils

Wash the oxide from the surface of the coil

Stainless steel is formed

▼ Select material

High quality 304 stainless steel raw materials

From the source to ensure the quality of products

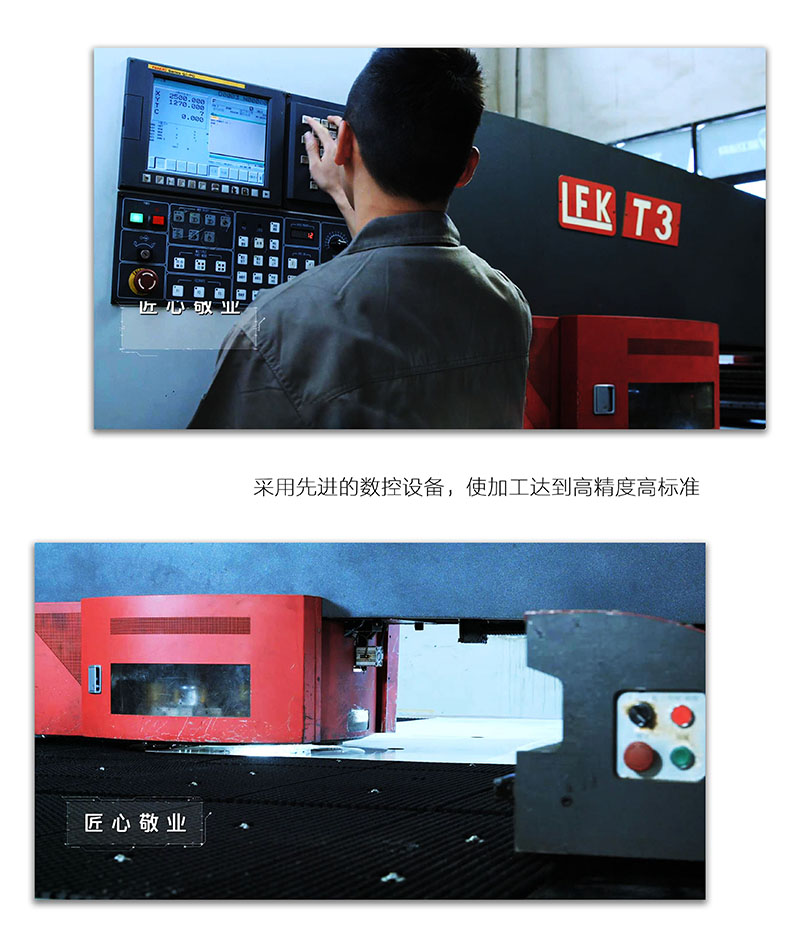

▼ Cutting

Opening the material is a piece of stainless steel into the first step

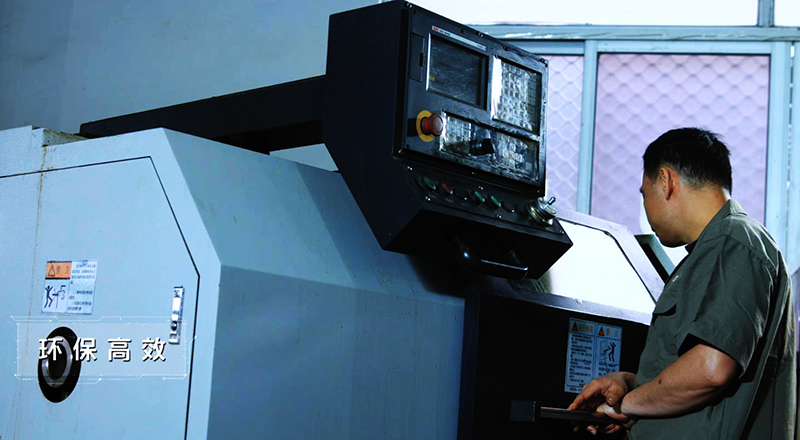

The workers use numerical control equipment

Divide the stainless steel into desired dimensions

Then the cut stainless steel for positioning hole

Reserve screw holes for the installation of drawers, handles and other parts

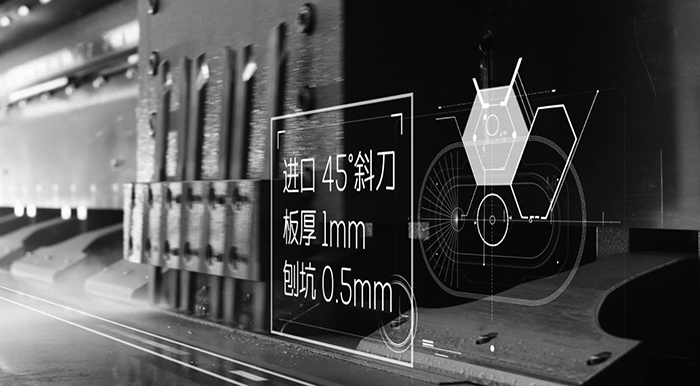

▼ Planed pit

To make the product bend more straight and vertical

CNC straight edge shaper is first used to plane a pit 0.5mm deep

Then use a large bending machine to bend accurately

To achieve stainless steel panel Angle and straight line clear

The stitching is close and three-dimensional

▼ Bending

The stainless steel is bent by a bending press

Bend to any Angle or shape as desired

Let the product present the perfect shape

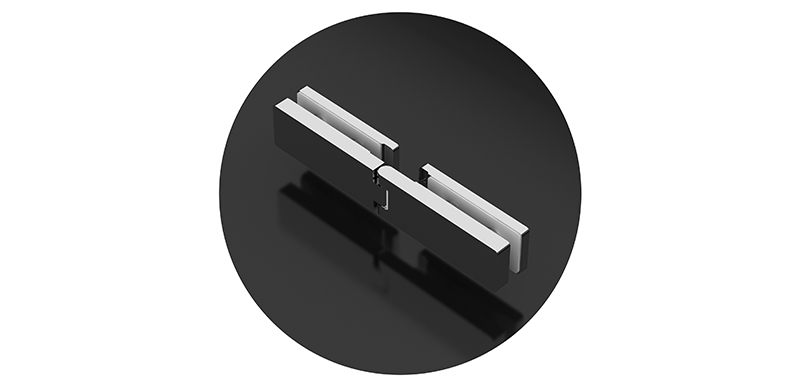

▼ Six sides in one

Let a stainless steel plate for one - sided molding

The folding surface is integrated to make the structure more precise and stable

Cabinet body does not have solder joint, concise and beautiful

▼ Hardware accessory processing

▼ Welding forming

Through the welding process

Weld pieces of stainless steel together

Cabinet body, picture frame, handle and other parts

▼ The plating color

Part of the accessories need to be coated with color

Make the product appearance more beautiful

Improve wear resistance and corrosion resistance

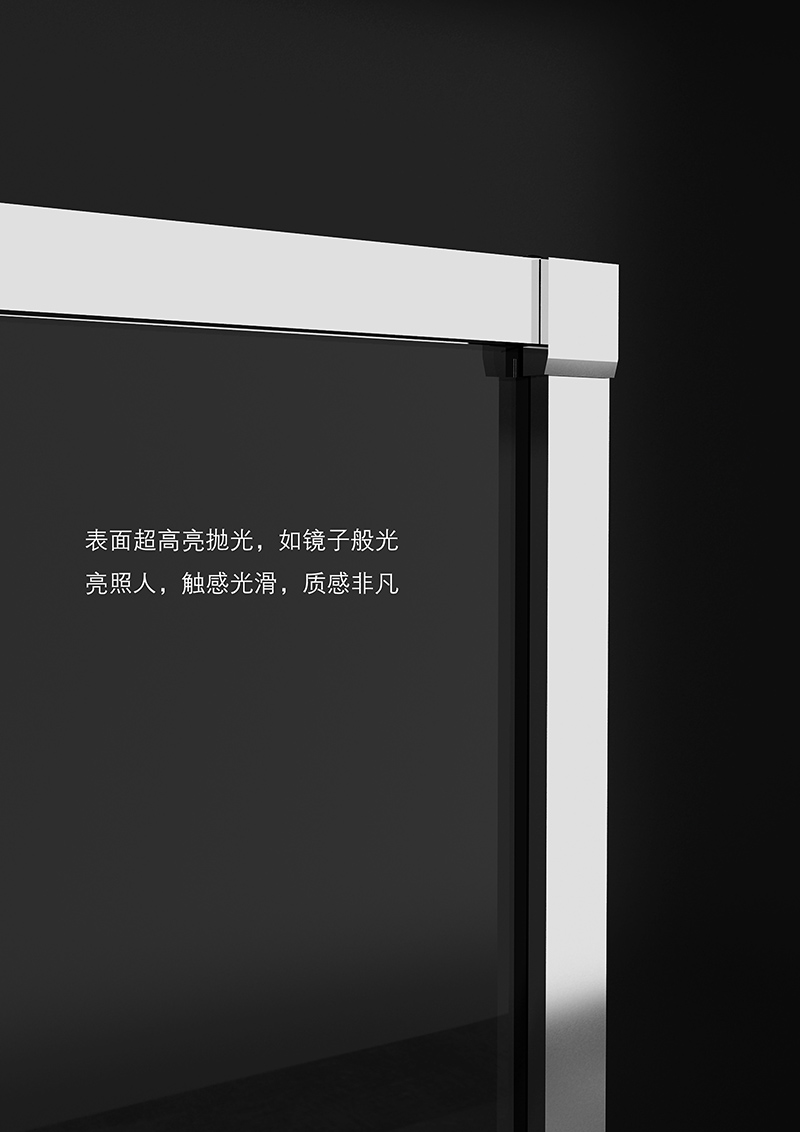

▼ Polishing grinding

To make the stainless steel surface more smooth and flat

The stainless steel surface needs to be polished and polished

After a dozen procedures

Rough grinding, fine grinding, grinding, super - fine grinding and other ingenuity

Make the surface achieve 8K mirror light effect

▼ Detection

The whole package is finished

But it has to go through a series of rigorous tests

Make sure every detail has no problem before leaving the factory

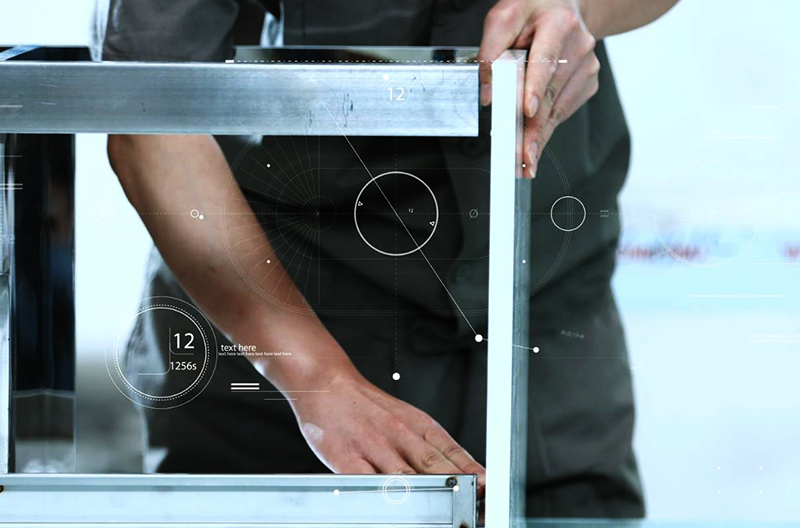

▼ The assembly

And then we assemble it

The processed parts of each product for general assembly

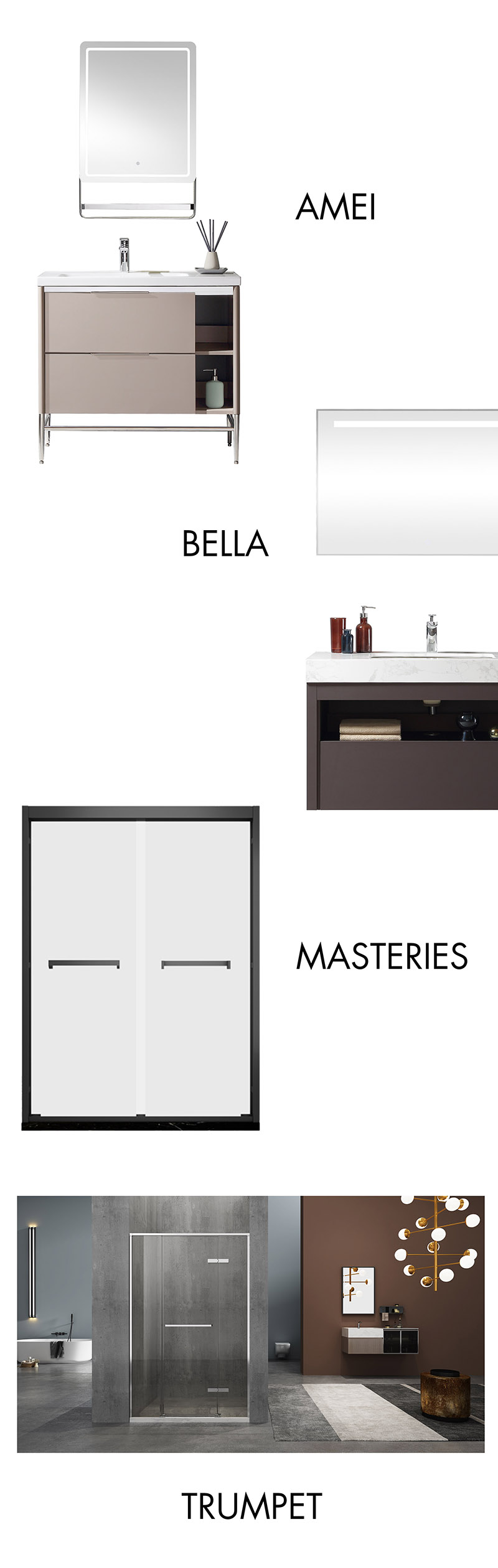

Form a complete bathroom cabinet or shower room

▼ packaging

Finally packaging

Wrap it with pearl cotton, pack it into a carton and put it into a foam board

Then nail the wooden frame, and then ready to load the factory

A stainless steel journey

From Red Earth to stainless steel plates

And then from sheet metal to stainless steel products

After thousands of hours of processing,

Of Hundreds of processes

To strive for perfection

In order to turn each product into a work of art

This is the artisan spirit of Pinwei

Copyright (C) Foshan benway materials industry Co., Ltd.